These days I am working on a new cabinet. The past few weeks I spent selecting material, slowly milling stock down to final dimensions, edge jointing, turning pieces over and over, looking for parts... it has been quite the trip already, though I am just getting going.

It really started with a rather large piece of spalted Chestnut that Robert spotted on our last wood run. With one look I was hooked on the delicate, psychedelic spalting, cream dappled with purplish brown and greyish blues. Though it was mostly too decayed to use, soft and full of bug holes, I clung onto this piece out of pure attraction, convinced that I would find a use for it, knowing at the very least I would simply admire it.

As I approached the completion of my second chair, I felt a bit tired. Unsure if I wanted to take on the complexity of a cabinet right away, I thought about some small simple projects, making some tools. Maybe a practice cabinet to refresh my memory. But my hesitation dissolved upon John starting his Composing piece this session, which reminded me of some of the most fun parts of our work: looking at wood, envisioning, finding clues in the grain as to what it could be.

So I declared, life is short, I want to a piece.

It came together one evening after a week of deep indecision over what to make. Robert pointed out a cabinet by JK which I had been talking about for some time, out of ash with glass and spalted maple in the two frame and panel doors. I could use the spalted Chestnut that I so adored for the door panels, and I had been wanting to practice frame and panel construction... it seemed like the right thing. I just needed something that would go well with the Chestnut, with its lovely matte texture and creamy tones.

Robert suggested Boxwood, something clicked, we knew it would be a perfect match. He brought out a plank from his shop and there it was, decided. Delighted and overwhelmed by the amazing wood in front of me, I had the beginnings of my cabinet in European Boxwood.

The pictures go a little way in showing how glorious this plank of wood is, so graciously gifted by my teacher. Four and half feet of wonderfully straight grain, three inches thick and ten inches wide, of a species rare in large sizes... dreamy! The colour is rich and warm, the smell like butter. I have noticed that insects passing through the shop love to stop by on the freshly milled pieces.

I took slices from the edge of the flat sawn board, giving me mostly quartered pieces. What a blessing to have thick stock. And just one knot to be worked around. I rejoiced in my good fortune, there would be enough wood to keep things full size. It would be tight, but just enough.

Then, disappointment when I resawed my piece of Chestnut. The graphics of spalting on the inside of the plank were unexciting, hardly as spectacular as I had imagined from the outside. As hard as I tried, it was difficult to find two pleasing sections while avoiding the extremely punky areas.

Robert and I started talking other options, though I would not give up on the Chestnut just yet. We looked at a couple of different woods from his shop and I pulled pieces from the wood collection at school. Nothing fit the cabinet I had in mind. Determined, I resawed a piece of spalted maple with similar tones. It could have worked, maybe, and in fact quite beautiful in itself, but did not quite match up to the Boxwood...

Robert perhaps sensed my discouragement, and told me he had one more option. I returned to the school after lunch to find this piece of spalted Beech sitting on my bench, recognising it to be wood from JK's shop.

Well, I cannot describe the feeling of receiving such a thing. In fact it is hard to talk about at all so I will keep it close to the chest.

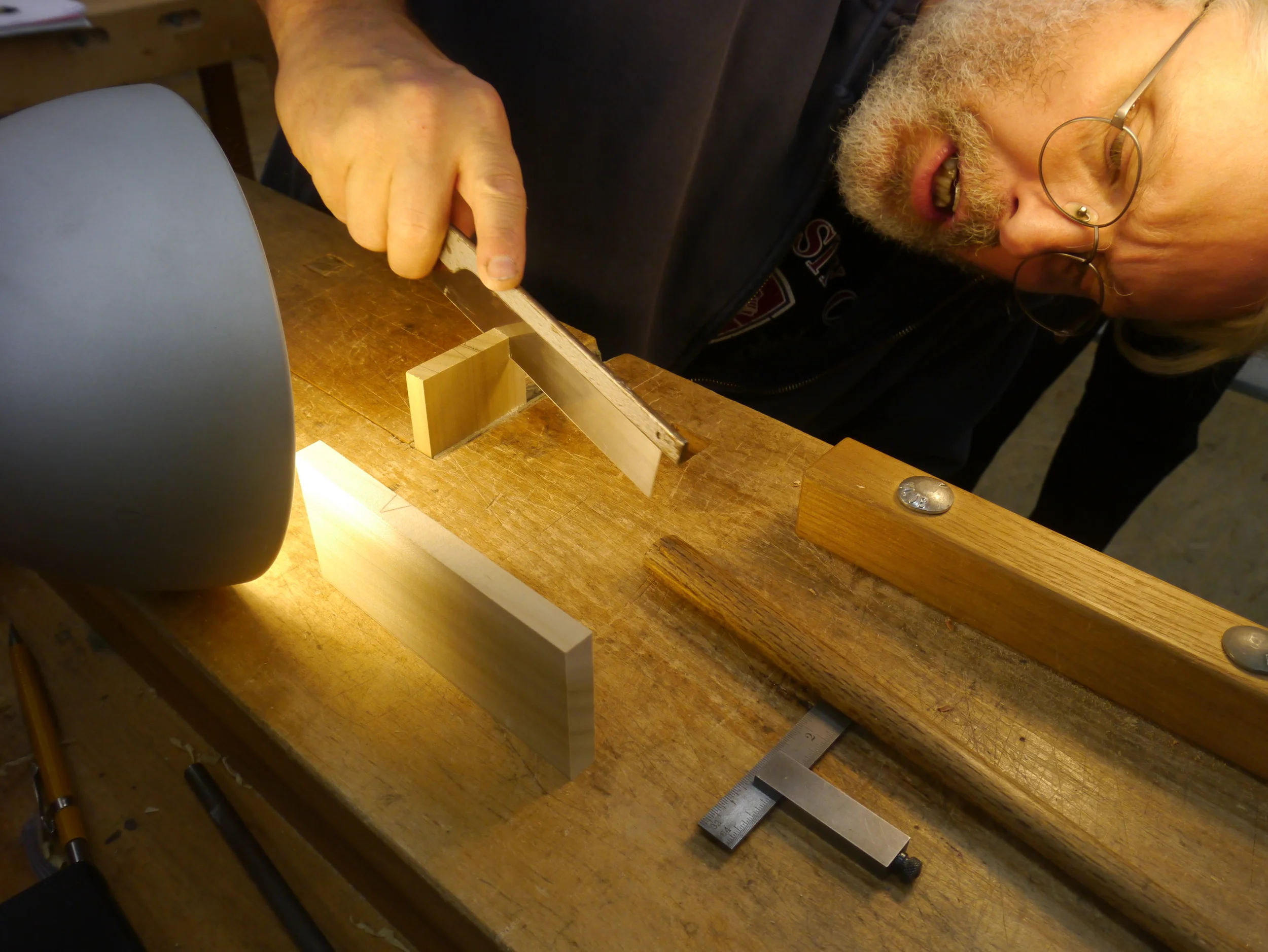

What I can share is that this gift resulted in the most enjoyable hour I have experienced in the shop to date - slowly and gently flattening this piece of wood by hand.